I bought this initially to

a) do quick PCB prototypes,

b) cut irregular holes into enclosures, and

c) for some very specific guitar jobs.

As it turned out I’ve used it progressively more for c), a little for b), and not at all yet for a).

The main guitar job I had in mind back then was to precisely plane the body and neck areas where they will be joined, as that’s something hard to get right with just manual tools.

But after playing more and more with this machine, I found myself applying it to many other tasks, while also improving my CAD/CAM skills.

The first step was to test the machine with the manual controls, so I made some exploratory cuts in regions that would be cut away anyway:

Next, I wrote a number of scripts in gcmc, i.e. one step above bare-bones g-code. This is used to cut a narrow trapezoid from the bridge to the end of the body to delineate the area where the strings would go.

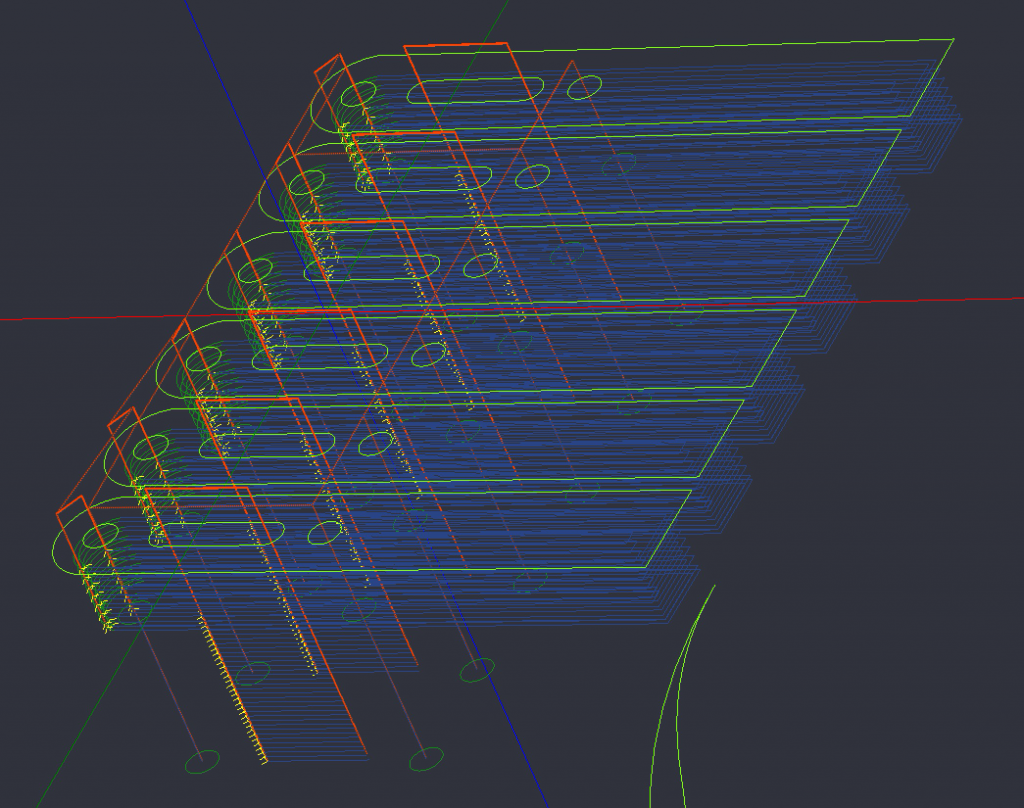

Then, after this turned out nicely, I wanted to try more advanced stuff. So I bought a simple CAM application (CamBam) that would allow me to design basic 2D shapes that would then be milled to a certain depth (what is commonly called a 2.5D approach).

I applied this first to pockets for the bridge elements to ensure that they are perfectly aligned.

The software can calculate a tool path and then export this to g-code, which can be read by the CNC controller, in this case Mach3.

Here’s the machine in action:

And here the result: